Production sections

The production departments below form a cluster with which we can produce anything from a simple engraving to the most complex design according to customer requirements.

Technical office

The technical office is the nerve centre of all production departments. Here each job is routed to the appropriate department. Any CAD file is translated almost automatically to machine code. Also, if you provide us with a drawing on paper, or any computer support, it can be processed by our engineering office until the desired result is obtained.

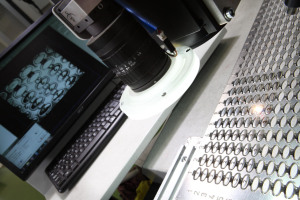

Laser engraving

Marcajes Telleria delivers immediately. Our clients? parts must remain on our premises the minimum time possible.  Marcajes Telleria distinguishes two types of laser engraving.

Marcajes Telleria distinguishes two types of laser engraving.

- Surface laser engraving: This type of engraving is indelible and vandal resistant. We try to get the tone and definition that the customer wishes by testing with different types of laser and adjusting the parameters. If possible more than one part is recommended; if we have more than one part, several tests can be performed. We make small, large, flat, cylindrical, conical parts… of metal or plastic.

- Deep laser engraving: Engraving in low relief and high relief on hardened steels, pre-treated steels, copper and graphite, for mould and die industries. These engravings are done and sent immediately.

Mechanical engraving

We dispose of mechanical engraving centres. Any drawing done on a CAD system, is automatically shown on any surface:  aluminium, brass, plastic and wood… We obtain perfectly clear engravings, which over the years never fade. This durability ensures that our control panels and flow-line diagrams remain unchanged in harsh industrial environments.

aluminium, brass, plastic and wood… We obtain perfectly clear engravings, which over the years never fade. This durability ensures that our control panels and flow-line diagrams remain unchanged in harsh industrial environments.

Aluminium machining

We can machine aluminium, brass and plastic plates of 2000×1000 in various thicknesses. The resulting parts are fully finished by means of countersinking, threading, chamfering, rounding of edges … All these operations are performed using numerical control units.

Shaping of aluminium and inserts

After years of experience in the electronics industry, we can make any type of front made entirely on our premises. We have a multitude of bolts, nuts, spacers, handles, etc in stock.

Painting booth

Our products can be provided with an anodized or painted finish. We use oven-dried and two-component paints to ensure optimum adhesion and durability of the paint. Careful work is essential to achieve a good surface finish.

Screen printing

Where engraving is not possible because of faded or numerous colours, screen printing is applied. We perform a high quality screen printing with optimum hardness on metals and plastics.