Laser marking

We perform marking on several types of metal or plastic parts. We have extensive experience in marking different  materials with different treatments, chromed, zinc-plated, painted … However, the first time a job is tackled, it is recommended to provide an extra part for testing and thus achieve a clear and consistent marking. Alternatively, indicate a place on the piece that will not be visible later so some preliminary testing can be done first.

materials with different treatments, chromed, zinc-plated, painted … However, the first time a job is tackled, it is recommended to provide an extra part for testing and thus achieve a clear and consistent marking. Alternatively, indicate a place on the piece that will not be visible later so some preliminary testing can be done first.

- (Español) Marcaje láser de pieza de inoxidable.

- (Español) Marcaje láser de tapa de plástico.

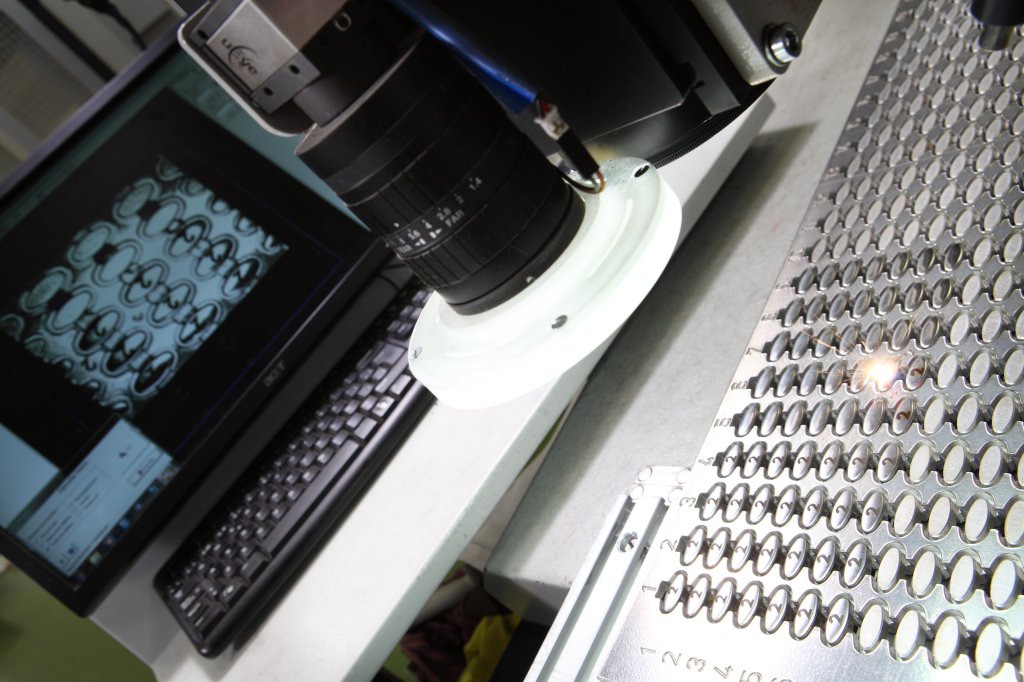

- (Español) Marcaje láser de nonius conico cromado.

- (Español) Marcaje láser de una pieza de plástico.

We engrave rubber or plastic injection moulds using laser technology with depths ranging from 0.1 mm to 0.25 mm, according to customer’s requirement. Also copper or graphite electrodes are made for greater depths.

Materials behave differently depending on the composition and hardness. For that reason it is recommended to indicate what material the mould is made of and what type of treatment it has undergone. If this is not known, indicate an area of the mould where a test can be performed or include an offcut with the same composition and treatment in the order.